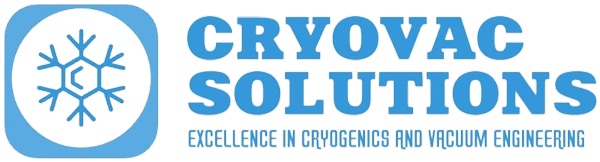

Custom Vacuum Chambers

Description:

A custom vacuum chamber refers to a specialized enclosure designed to create and maintain a low-pressure environment, typically for industrial processes, scientific research or testing purposes.

Applications:

Custom vacuum chambers are used in a wide range of applications across various industries, including semiconductor manufacturing, materials science research, aerospace testing, and vacuum coating processes. The versatility and customizability of these chambers make them indispensable tools for numerous scientific and industrial endeavours.

Overall, designing and constructing a custom vacuum chamber requires careful consideration of various factors to ensure that the chamber meets the specific requirements of the intended application while maintaining safety and reliability.

Ours great team has vast experience to design, build, and operate custom vacuum chambers effectively.

Enquiry Now

Features

- Material Selection: Vacuum chambers are typically constructed from materials such as stainless steel, aluminum, or glass, depending on factors such as desired vacuum level, required cleanliness, and compatibility with the processes or experiments being conducted.

- Design Considerations: The design of a custom vacuum chamber depends on several factors, including the size and shape of the objects or samples to be contained within it, the required vacuum level, temperature requirements, and any additional features such as windows for observation or ports for introducing gases or other materials.

- Vacuum Pumping System: A vacuum chamber requires a pumping system to remove air and other gases from the enclosure, creating the desired low-pressure environment. Different types of vacuum pumps, such as rotary vane pumps, turbomolecular pumps, or cryogenic pumps, may be used depending on the specific application and vacuum level requirements.

- Sealing Mechanisms: Proper sealing is essential to maintain the vacuum within the chamber. Custom vacuum chambers may utilize a variety of sealing mechanisms, such as O-rings, gaskets, or metal seals, depending on factors such as vacuum level, temperature, and compatibility with the materials being processed or tested.

- Control and Monitoring Systems: Custom vacuum chambers often incorporate control and monitoring systems to regulate parameters such as pressure, temperature, and gas composition within the enclosure. These systems may include sensors, valves, and automated control systems to maintain the desired conditions throughout the duration of an experiment or process.

- Safety Considerations: Operating a vacuum chamber safely requires adherence to proper procedures and safety protocols. This includes considerations such as proper venting procedures, monitoring for leaks, and ensuring the integrity of the chamber and associated equipment to prevent accidents or equipment damage.

Related products

Feedthroughs

A vacuum feedthrough is a crucial component in systems where electrical, mechanical, or fluid signals need to be transmitted into or out of a vacuum environment without compromising the vacuum integrity. These devices are commonly used in various industries, including scientific research, semiconductor manufacturing, aerospace, and materials processing.

Enquiry Now

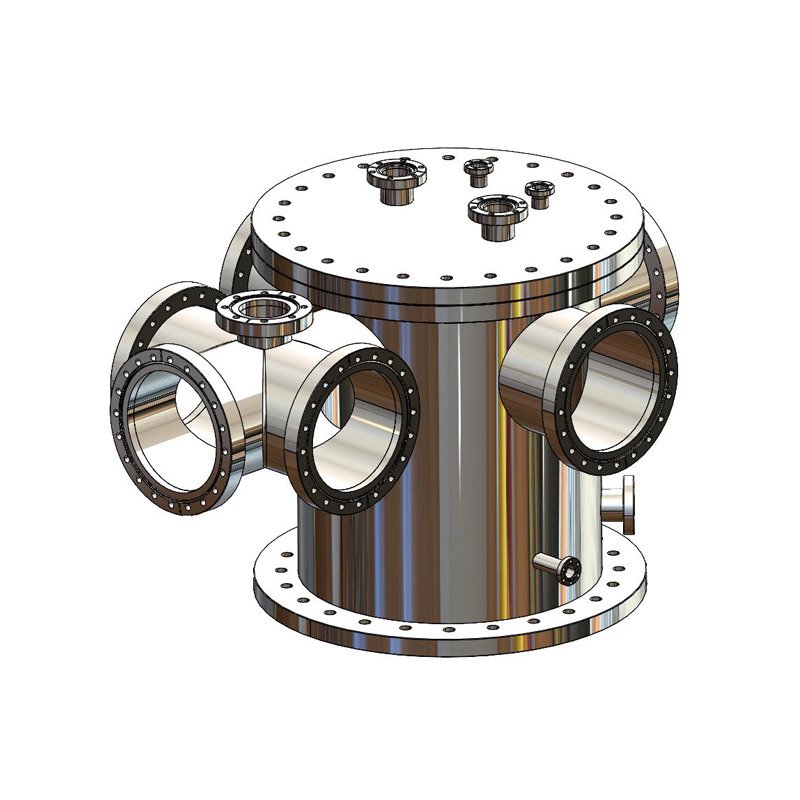

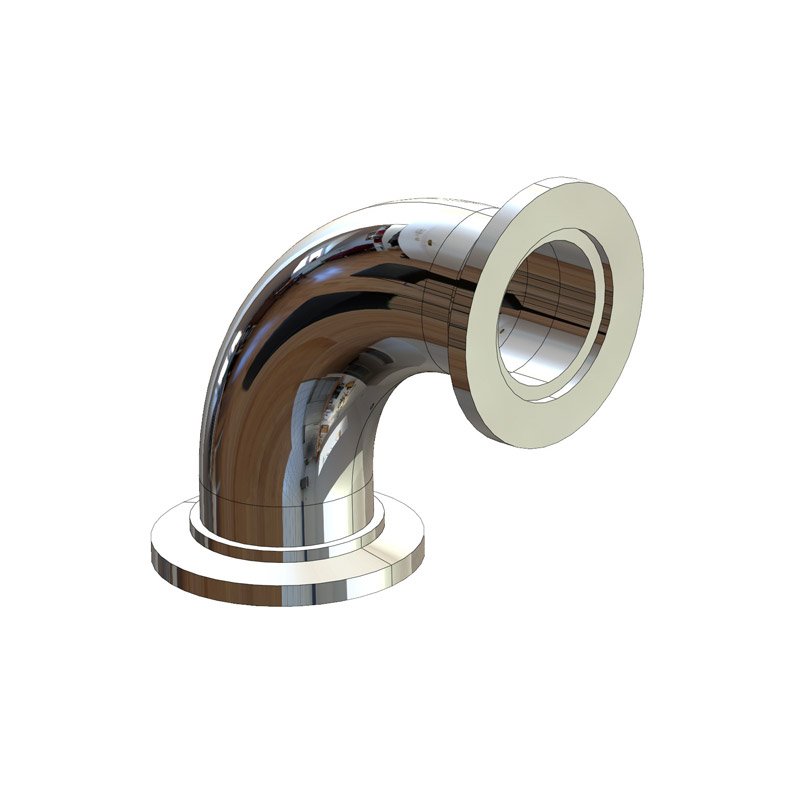

Flanges and Fittings

Flanges and Fittings play crucial roles in the construction and operation of vacuum systems. They provide means for connecting different components, chambers, and instruments within the vacuum system while maintaining a high vacuum or ultra-high vacuum environment.

Some details about fittings and flanges commonly used in vacuum systems:

- Flanges: Flanges are flat, typically circular plates with bolt holes around the perimeter. They are used to connect vacuum chambers, components, and instruments together. Flanges come in various sizes, shapes, and materials to accommodate different vacuum system requirements. Common materials for flanges include stainless steel, aluminum, and glass.

- Fittings: Fittings are components used to connect different vacuum system elements such as vacuum pumps, gauges, valves, and chambers. They come in various shapes and sizes to accommodate different vacuum system configurations. Common types of fittings include elbows, tees, crosses, reducers, and adapters.

Enquiry Now

LHe & LN2 Dewars

At CryoVac Solutions, we specialize in providing high-quality cryogenic solutions tailored to meet the needs of various industries.

Our range of Liquid Helium (LHe) and Liquid Nitrogen (LN2) Dewars are designed to deliver exceptional performance and reliability for your most demanding applications. With years of experience and a commitment to innovation, we ensure that our products meet the highest standards of quality and safety.

Enquiry Now

Vacuum Pumps

1. Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are designed for a variety of applications requiring robust and reliable performance. These pumps are ideal for laboratory use, industrial processes, and more.

2. Scroll Vacuum Pumps

Our scroll vacuum pumps offer oil-free operation and high efficiency, making them suitable for cleanroom environments, semiconductor manufacturing, and other sensitive applications.

3. Turbo Molecular Vacuum Pumps

Turbo molecular vacuum pumps provide ultra-high vacuum levels essential for advanced scientific research, thin-film deposition, and high-tech manufacturing.

4. Diaphragm Vacuum Pumps

Our diaphragm vacuum pumps are ideal for applications requiring chemical resistance and oil-free operation, such as in laboratories and chemical processing.

Enquiry Now

View Ports

Our state-of-the-art vacuum view ports, essential for industries reliant on precise control and visibility within vacuum chambers.

Built to exacting standards, our view ports provide unparalleled clarity into critical processes, ensuring you can monitor operations with confidence and precision.