Flanges and Fittings

Description:

Flanges and Fittings play crucial roles in the construction and operation of vacuum systems. They provide means for connecting different components, chambers, and instruments within the vacuum system while maintaining a high vacuum or

ultra-high vacuum environment.

Some details about fittings and flanges commonly used in vacuum systems:

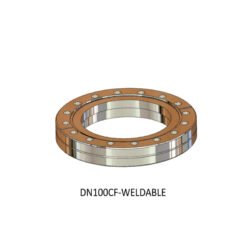

- Flanges: Flanges are flat, typically circular plates with bolt holes around the perimeter. They are used to connect vacuum chambers, components, and instruments together. Flanges come in various sizes, shapes, and materials to accommodate different vacuum system requirements. Common materials for flanges include stainless steel, aluminum, and glass.

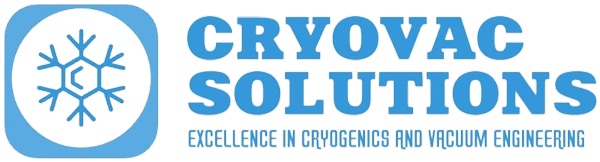

- Fittings: Fittings are components used to connect different vacuum system elements such as vacuum pumps, gauges, valves, and chambers. They come in various shapes and sizes to accommodate different vacuum system configurations. Common types of fittings include elbows, tees, crosses, reducers, and adapters.

Enquiry Now

Types of Flanges:

- KF flanges are commonly used in low to medium vacuum applications. They feature a quick-release clamp mechanism that allows for easy assembly and disassembly of vacuum components.

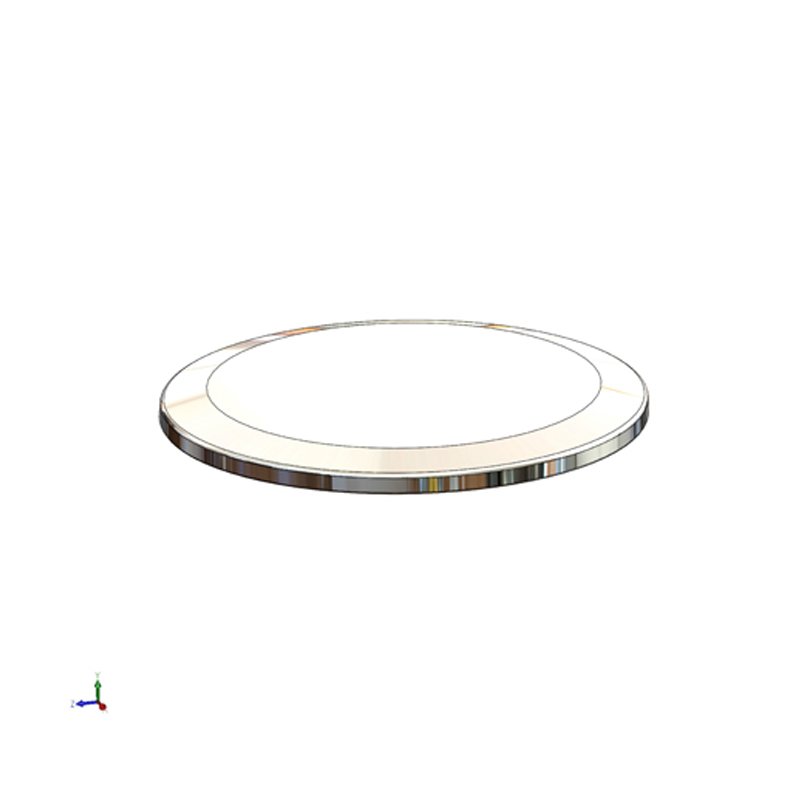

- CF flanges are designed for high vacuum and ultra-high vacuum applications. They use knife-edge seals and copper gaskets to create a high vacuum-tight seal. CF flanges are bolted together using stainless steel bolts and nuts.

- ISO-K flanges are standardized vacuum flanges often used in industrial vacuum systems. They feature a rubber O-ring seal and clamping system for easy assembly.

- Similar to ISO-K flanges, ISO-F flanges are also standardized vacuum flanges but feature a metal gasket seal instead of an Oring seal.

Related products

CVD/PVD Furnace

At CryoVac solutions, we specialize in providing top-quality and high-performance coating solutions that enhance the durability, functionality, and aesthetic appeal of materials tailored for chemical vapor deposition (CVD) and physical vapor deposition (PVD) processes. With a commitment to excellence and customer satisfaction, we work closely with clients to understand their challenges and provide tailored solutions that drive success.

Enquiry Now

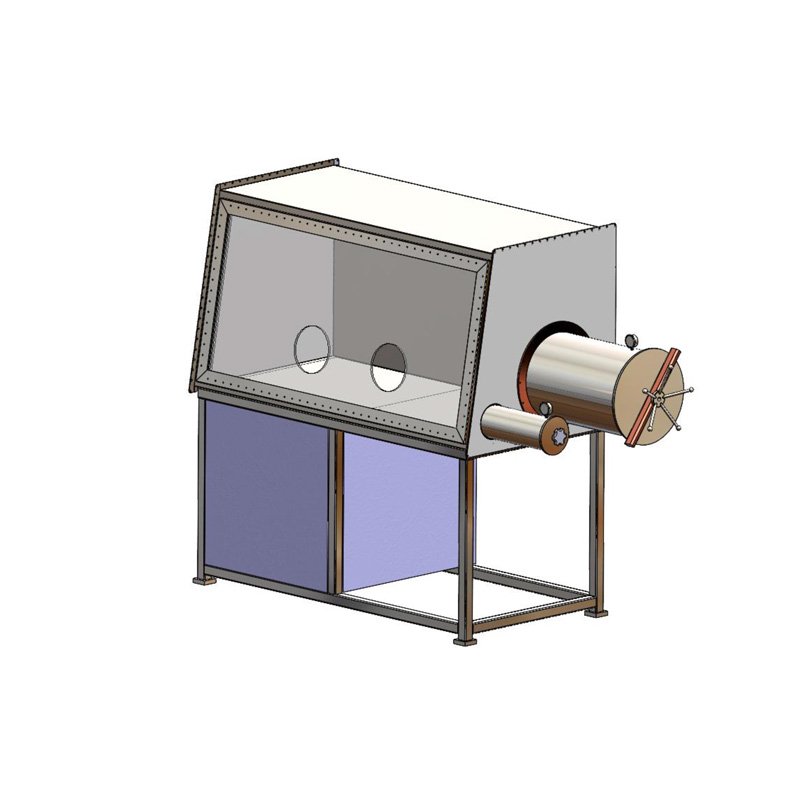

Glove Box

A glove box is a sealed container with built-in gloves that allows users to handle objects in a controlled environment. These boxes are typically used in laboratories, cleanrooms, and manufacturing facilities where it's necessary to manipulate objects in a controlled atmosphere, such as under inert gas or in a low-humidity environment.

Regular maintenance and inspection of the glove box, including checking for leaks and ensuring the integrity of gloves and seals, are also important for safe operation.

Enquiry Now

LHe & LN2 Dewars

At CryoVac Solutions, we specialize in providing high-quality cryogenic solutions tailored to meet the needs of various industries.

Our range of Liquid Helium (LHe) and Liquid Nitrogen (LN2) Dewars are designed to deliver exceptional performance and reliability for your most demanding applications. With years of experience and a commitment to innovation, we ensure that our products meet the highest standards of quality and safety.

Enquiry Now

Vacuum insulated Custom LHe & LN2 Transfer Lines

Custom vacuum-insulated liquid helium (LHe) and liquid nitrogen (LN2) transfer lines are specialized components designed to transport cryogenic fluids with minimal thermal losses. These transfer lines are essential in various applications, including research laboratories, medical equipment, and industrial processes. We do Customization also such as Length, diameter, and specific connection types can be customized to meet the exact requirements of the application. Custom bends and routing options to fit spatial constraints.

Enquiry Now

View Ports

Our state-of-the-art vacuum view ports, essential for industries reliant on precise control and visibility within vacuum chambers.

Built to exacting standards, our view ports provide unparalleled clarity into critical processes, ensuring you can monitor operations with confidence and precision.