LHe & LN2 Dewars

Description:

At CryoVac Solutions, we specialize in providing high-quality cryogenic solutions tailored to meet the needs of various industries.

Our range of Liquid Helium (LHe) and Liquid Nitrogen (LN2) Dewars are designed to deliver exceptional performance and reliability for your most demanding applications. With years of experience and a commitment to innovation, we ensure that our products meet the highest standards of quality and safety.

Enquiry Now

Features

- Our Liquid Helium Dewars are engineered for optimal thermal insulation and efficient storage. Whether for scientific research, medical applications, or industrial processes, our LHe Dewars provide the perfect solution for your cryogenic storage needs.

- Designed for versatility and efficiency, our Liquid Nitrogen Dewars cater to a wide range of applications, from laboratory experiments to industrial applications. Our LN2 Dewars are built to deliver superior performance and ease of use.

Related products

Custom Vacuum Chambers

A custom vacuum chamber refers to a specialized enclosure designed to create and maintain a low-pressure environment, typically for industrial processes, scientific research or testing purposes.

Applications:

Custom vacuum chambers are used in a wide range of applications across various industries, including semiconductor manufacturing, materials science research, aerospace testing, and vacuum coating processes. The versatility and customizability of these chambers make them indispensable tools for numerous scientific and industrial endeavours.

Overall, designing and constructing a custom vacuum chamber requires careful consideration of various factors to ensure that the chamber meets the specific requirements of the intended application while maintaining safety and reliability.

Ours great team has vast experience to design, build, and operate custom vacuum chambers effectively.

Enquiry Now

Feedthroughs

A vacuum feedthrough is a crucial component in systems where electrical, mechanical, or fluid signals need to be transmitted into or out of a vacuum environment without compromising the vacuum integrity. These devices are commonly used in various industries, including scientific research, semiconductor manufacturing, aerospace, and materials processing.

Enquiry Now

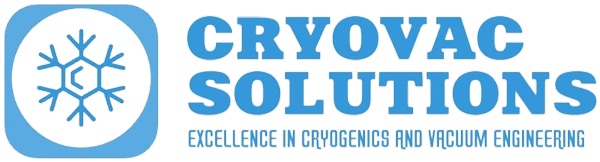

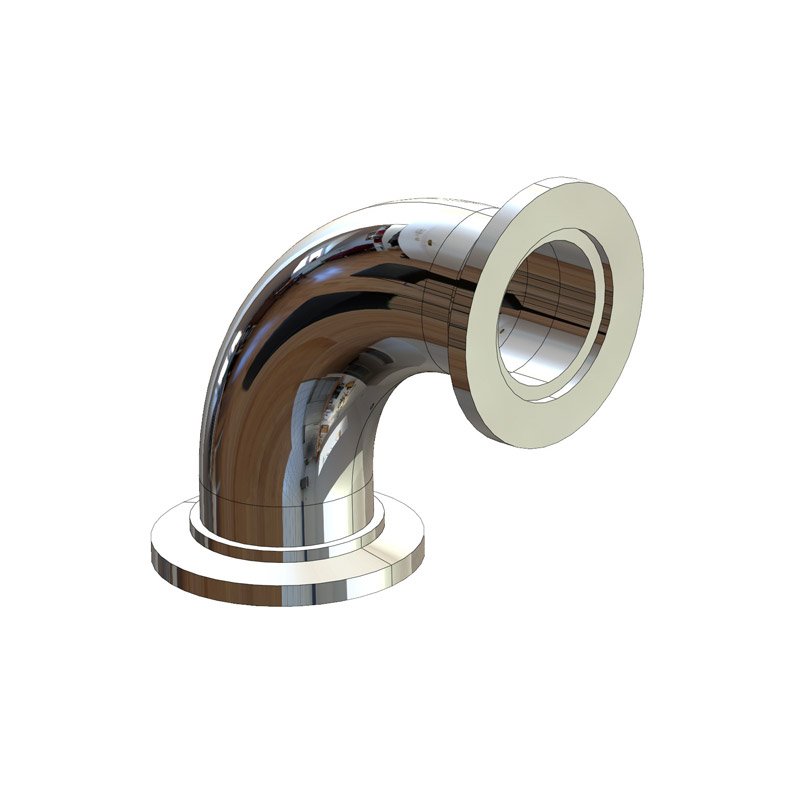

Flanges and Fittings

Flanges and Fittings play crucial roles in the construction and operation of vacuum systems. They provide means for connecting different components, chambers, and instruments within the vacuum system while maintaining a high vacuum or ultra-high vacuum environment.

Some details about fittings and flanges commonly used in vacuum systems:

- Flanges: Flanges are flat, typically circular plates with bolt holes around the perimeter. They are used to connect vacuum chambers, components, and instruments together. Flanges come in various sizes, shapes, and materials to accommodate different vacuum system requirements. Common materials for flanges include stainless steel, aluminum, and glass.

- Fittings: Fittings are components used to connect different vacuum system elements such as vacuum pumps, gauges, valves, and chambers. They come in various shapes and sizes to accommodate different vacuum system configurations. Common types of fittings include elbows, tees, crosses, reducers, and adapters.

Enquiry Now

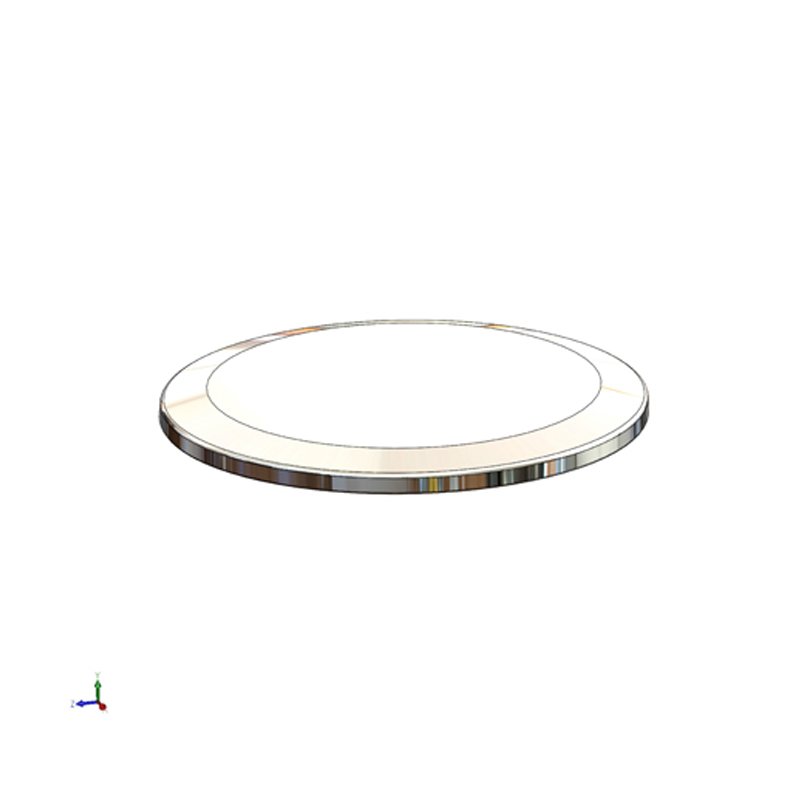

Glove Box

A glove box is a sealed container with built-in gloves that allows users to handle objects in a controlled environment. These boxes are typically used in laboratories, cleanrooms, and manufacturing facilities where it's necessary to manipulate objects in a controlled atmosphere, such as under inert gas or in a low-humidity environment.

Regular maintenance and inspection of the glove box, including checking for leaks and ensuring the integrity of gloves and seals, are also important for safe operation.

Enquiry Now

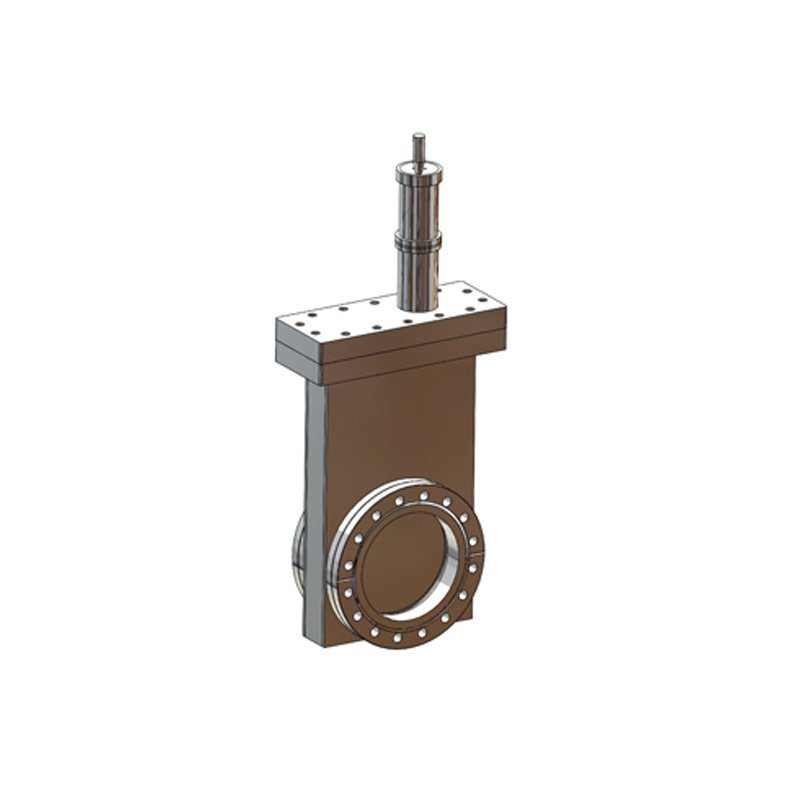

Vacuum Valves

Vacuum valves are essential components in systems that require the control and regulation of vacuum pressure. They are used in a variety of applications, including laboratory research, industrial processes, semiconductor manufacturing, and vacuum packaging.

Selection Criteria

When selecting a vacuum valve, consider the following criteria:

- 1. Vacuum Level: Ensure the valve can operate effectively at the desired vacuum pressure.

- 2. Flow Rate: Choose a valve that can handle the required flow rate.

- 3. Material Compatibility: Ensure the valve materials are compatible with the process gases or liquids.

- 4. Temperature Range: Select a valve that can withstand the operating temperature conditions.

- 5. Actuation Method: Decide between manual, pneumatic, or electric actuation based on the application needs.